MANUFACTURING COMPETENCE

An essential link in the supply chain between plastic converters and the polymer producers is the production of compounds and masterbatch. Therefore, we carefully select the pigments, additives, keeping in mind end-users' performance and the process condition to achieve the best result. The batches are tested on the parameters like Dispersion, MFI, Colour Fastness, Heat Fastness, Density, Carbon Content, Opacity, Whiteness, and Gloss etc., to maintain the excellent consistency in every batch.

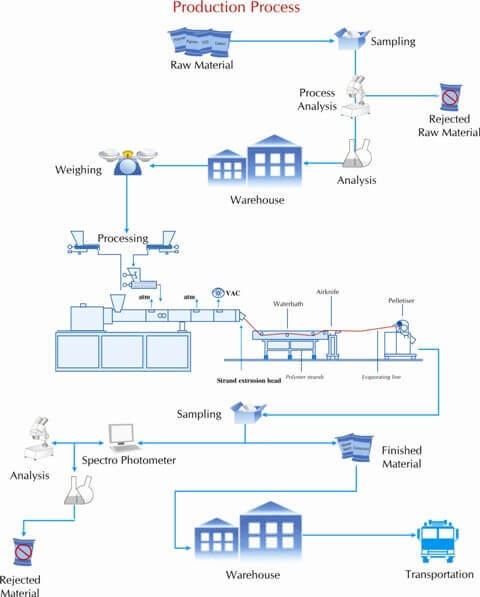

With our extensive process know-how we adapt all the process steps from dosing, through raw materials feeding, conveying, melting, dispersing, homogenizing, devolatilizing, pressure buildup, filtering and pelletizing exactly to the requirements of the masterbatch recipes. This gives you exactly what you expect - a compounding system that is optimally tailored to your application.

The processing of masterbatch makes great demands on the compounding process. The pigment and additive parts must be mixed into the base polymer absolutely homogeneously. The co-rotating twin screw extruders from Coperion, formerly Werner & Pfleiderer, are particularly suitable for the processing of masterbatch because of their excellent mixing properties and gentle product handling.

From the laboratory extruder to the production machine with high throughput rates, the Coperion twin screw extruders all operate extremely economically. Features such as the quick change feed hopper, the die head with swivel device and the quick change ZS-B side feeder enable fast, easy cleaning of the extruder and therefore economical formulation and colour changes.